My name is Gabriel Lipkowitz. I am an assistant professor at the National University of Singapore in the Division of Industrial Design leading the Interactive 3D Design Lab (i3D). i3D seeks to bridge the gap between design and development in the context of emerging interactive 3D technologies such as real-time 3D, generative 3D, and spatial computing, among other areas.

i3D is hiring! Interested prospective PhD students, please tell me about yourself here! And interested undergraduate and master's students, here!

In my free time, I love cycling 🚴, visiting art museums 🏛️, and seeking out good coffee ☕️. More than happy to chat about anything related to research or outside of research!

Highlighted Work

Generative Lattice Design for Large Format 3D printing

On exhibit at San Jose State University Art Gallery.Gabriel Lipkowitz, Alvin Huang

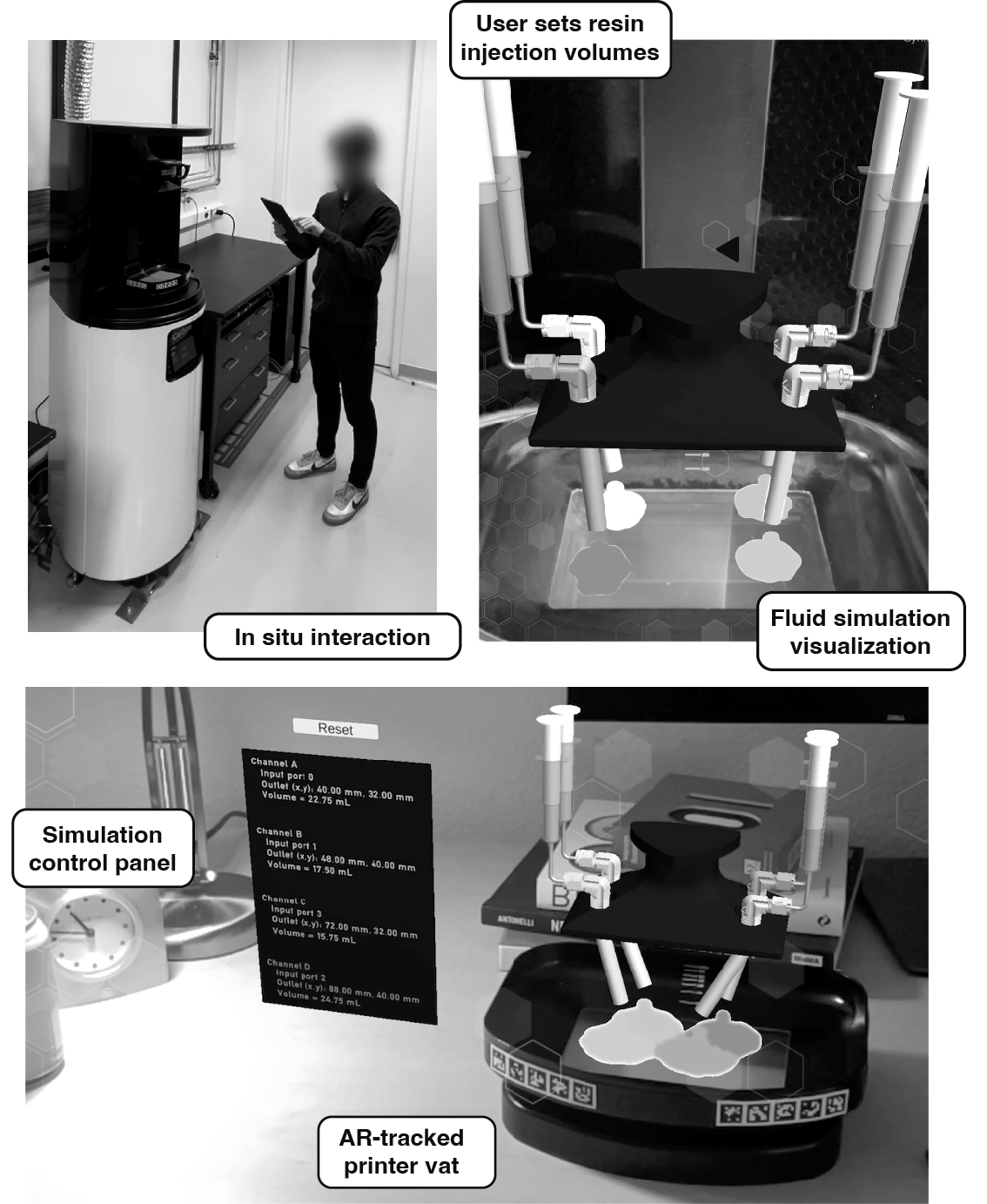

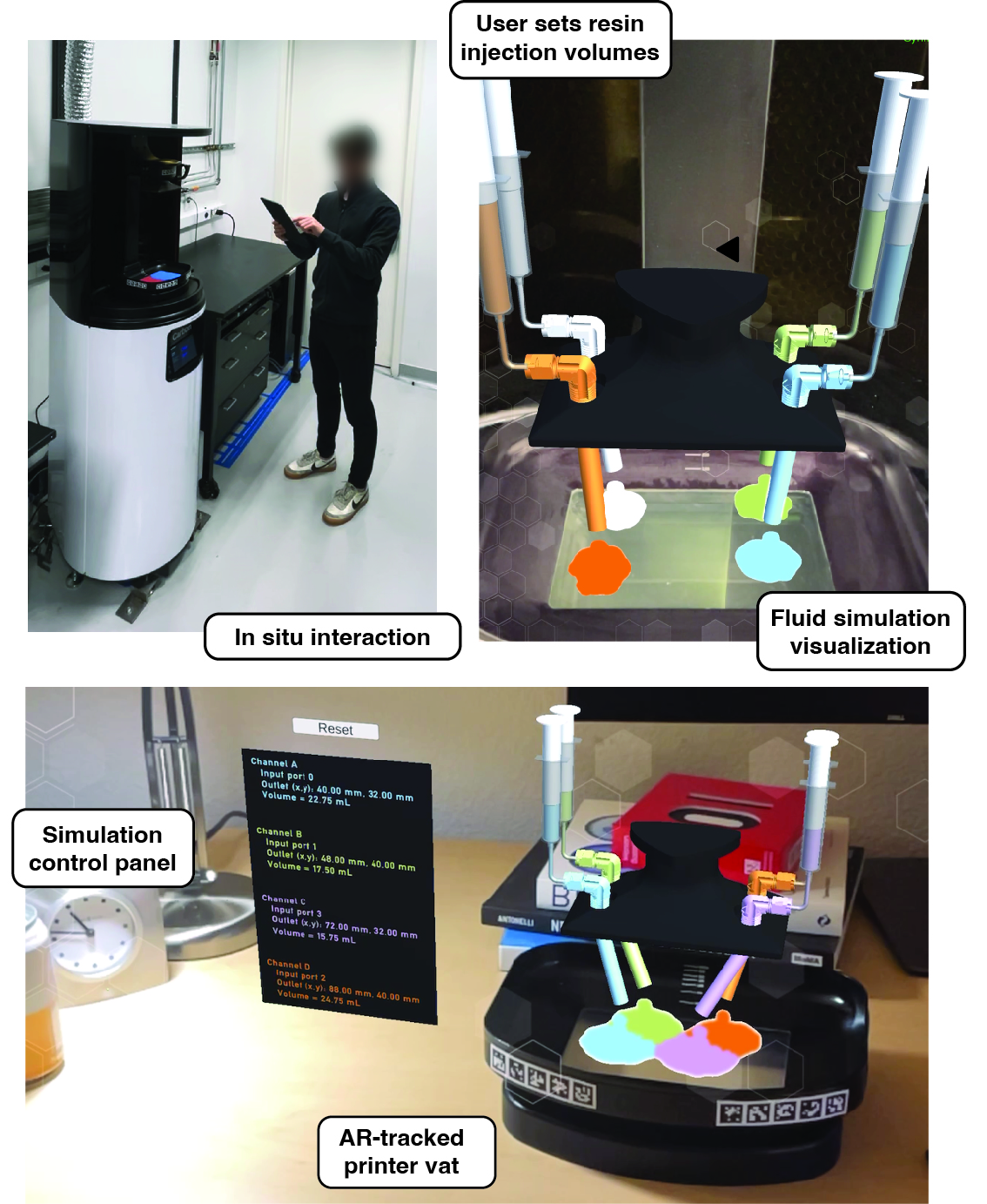

Palette-PrintAR: augmented reality fluidic design for multicolor resin 3D printing

2024 CHI Conference on Human Factors in Computing Systems.Gabriel Lipkowitz and Joseph M. DeSimone

Injection continuous liquid interface production of 3D objects

Gabriel Lipkowitz, Tim Samuelsen, Kaiwen Hsiao, Brian Lee, Maria T. Dulay, Ian Coates, Harrison Lin, William Pan, Geoffrey Toth, Lee Tate, Eric S. G. Shaqfeh, Joseph M. DeSimone

Publications

Computational Design

🆕 Lipkowitz, G. (2024). "Palimpsest: a spatial user interface toolkit for cohering tracked physical entities and interactive 3D content" ACM Symposium on User Interface Software and Technology.

🆕 Lipkowitz, G. (2024). "RubiXR: Demonstration of dynamic task augmentation through co-design of interactive 3D content and 3D user interfaces" ACM Symposium on Spatial User Interaction.

Lipkowitz, G., and DeSimone, J. (2024). "Palette-PrintAR: augmented reality fluidic design for multicolor resin 3D printing" Accepted at 2024 CHI Conference on Human Factors in Computing Systems.

Lipkowitz, G., Shaqfeh, E. and DeSimone, J. (2023). "Palette-PrintAR: an augmented reality fluidic design tool for multicolor resin 3D printing" In UIST '23 Adjunct: Adjunct Proceedings of the 36th Annual ACM Symposium on User Interface Software and Technology.

Lipkowitz, G., Shaqfeh, E. and Desimone., J. (2023) "Paraflow: A Computational Design Tool for Support-free Multimaterial 3D Printing" Extended Abstracts of the 2023 CHI Conference on Human Factors in Computing Systems.

Lipkowitz, G., Shaqfeh, E., & DeSimone, J. (2022) "Generative co-design for microfluidics-accelerated 3D printing" In Proceedings of the 7th Annual ACM Symposium on Computational Fabrication (pp. 1-3).

Lipkowitz, G., Samuelsen, T., Hsiao, K., Dulay, M. T., Coates, I., Pan, W., ... & DeSimone, J. (2022). "Digital Microfluidic Design for Injection Continuous Liquid Interface Production of 3D Objects" In 2022 International Solid Freeform Fabrication Symposium.

Computational Fabrication

Lipkowitz, G., Krishna, N. Coates, I. Shaqfeh, E. and DeSimone, J. (2023) "Printing atom-efficiently: faster fabrication of farther unsupported overhangs by fluid dynamics simulation" In Proceedings of the 7th Annual ACM Symposium on Computational Fabrication.

Lipkowitz, G., Samuelsen, T., Hsiao, K., Lee, B., Dulay, M. T., Coates, I., ... & DeSimone, J. M. (2022). "Injection continuous liquid interface production of 3D objects" Science Advances, 8(39), eabq3917.

Lipkowitz, G., Shaqfeh, E.S.G. and DeSimone, J.M.D.(2023) "Fluidics-Informed Fabrication: A Novel Co-design for Additive Manufacturing Framework." International Conference on Human-Computer Interaction. Cham: Springer Nature Switzerland.

Hsiao, K., Lee, B. J., Samuelsen, T., Lipkowitz, G., Kronenfeld, J. M., Ilyn, D., ... & DeSimone, J. M. (2022). "Single-digit-micrometer-resolution continuous liquid interface production." Science Advances, 8(46).

Lee BJ, Hsiao K, Lipkowitz G, Samuelsen T, Tate L, DeSimone JM. (2022) "Characterization of a 30 µm pixel size CLIP-based 3D printer and its enhancement through dynamic printing optimization" Addit Manuf.

Lipkowitz, G. Hennum, K.S. Piva, E. and Schofield, E. (2021) “Numerical Modelling of moisture loss during controlled drying of marine archaeological wood” Forests 2021, 12(12), 1662

Computational biology

Winer, B.Y., Huang, T.S., Pludwinski, E., Wojcik, F. Lipkowitz, G. , Parekh, A., Cho, C., Shrirao, A., Muir, T., Novik, E., Ploss, A. (2017) “Long-term persistent hepatitis B virus infection in a scalable micro-well primary hepatocyte coculture system” Nature Communications, 8:125.

Magoro, T. Dandekar, A., Jennelle, L. Bajaj, R. Lipkowitz, G. Angelucci, A. Bessong, P. and Hahn, Y. (2019) “IL-1β/TNF-α/IL-6 inflammatory cytokines promote STAT1-dependent induction of CH25H in zika virus-infected human macrophages” J. Biol. Chem.

Winer, B.Y. Gaska, J. Lipkowitz, G. Bram, Y. Parekh, A. Parsons, L. Leach, R. Jindal, R. Cho, C. Shrirao, A. Novik, E. Schwartz, R. Ploss, A. (2019) “Transcriptomic analysis of acute and chronic HBV and HBV/HDV co-infections in self-assembling primary human hepatocyte co-cultures” Hepatology.

Winer, B.Y. Parekh, A. Heller, B. Lipkowitz, G. Guo, R. Cho, C. Shrirao, A. Pludwinski, E. Novik, E. Ploss, A. (2018) “Persistent Hepatitis B virus infection in self-assembling microscale primary hepatocyte co-culture” Drug Metabolism and Pharmacokinetics.